Pharmaceutical

Pharma products are subject to a variety of stringent laws and regulation. Aberration results in harm to patients, attracts heavy penalties, loss of trust, goodwill and sometimes closure of the firm. The manual inspection has been replaced by Camera Vision inspection to provide consistent results, remove bottle necks in production and reduce quality cost.

Our contribution in providing precise, reliable and economical solutions has helped in ensuring quality compliance such as CFR21.TEJ incidentally has a Vibrant in house R&D department recognized by Department of Scientific & Industrial Research, With an experience of 20 years in design and manufacturing of Vision Inspection SPMs (Special Purpose Machines). This is complimented with more than three decades of being a major Automation System house and experience of Robotics. With high standards maintained consistently, the machines developed by TEJ has become a Vision Inspection bench mark in the Pharma industry.

Our Projects

VIAL & AMPOULE INSPECTION SYSTEM

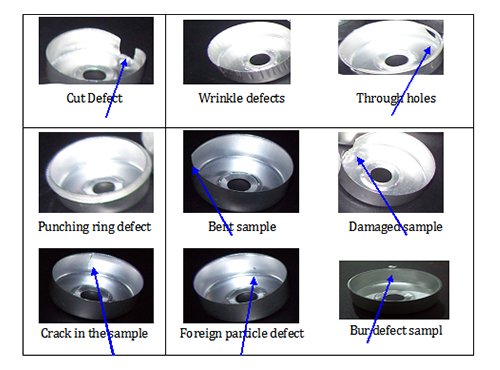

Developed by the TIVS is a comprehensive inspection solution for the visualdefects occurring in sample which is giving by you. The Inspection system is compact in design and can be easilyintegrated into existing production lines.

INSPECTION CAPABILITY

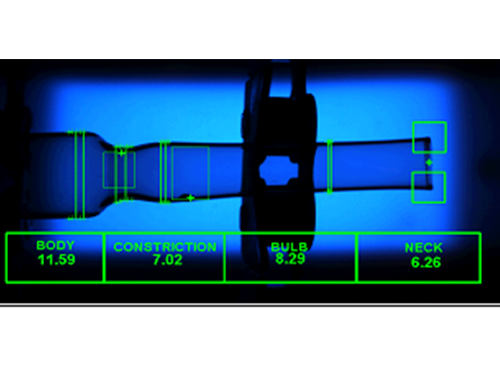

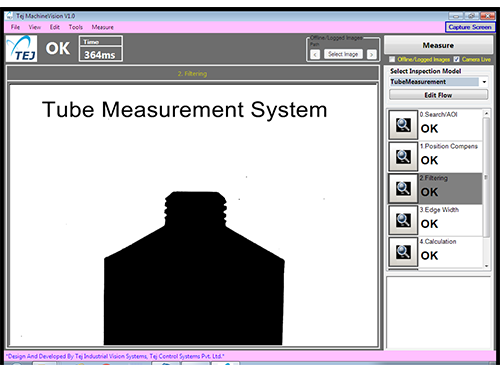

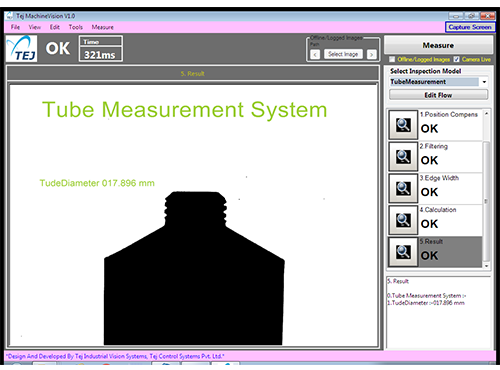

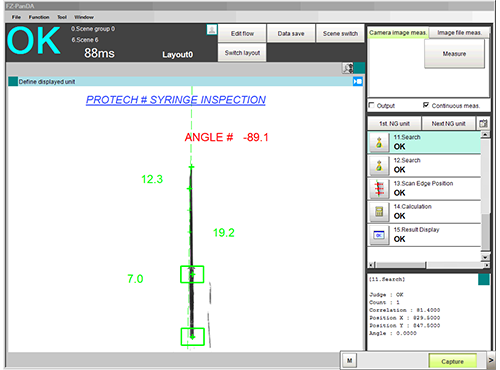

Dimension checking

- Body Dia

- Outer Dia of Lip

- Lip thickness

- Inner Dia of Lip

- Neck Dia

- Height

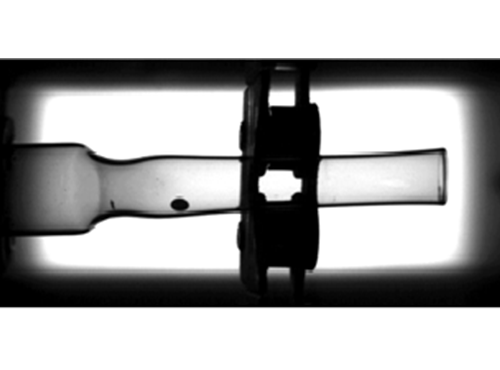

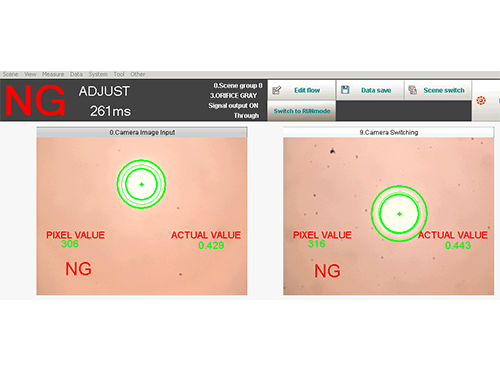

CAMERA RESULTS FOR GOOD AND BAD VIAL SAMPLE

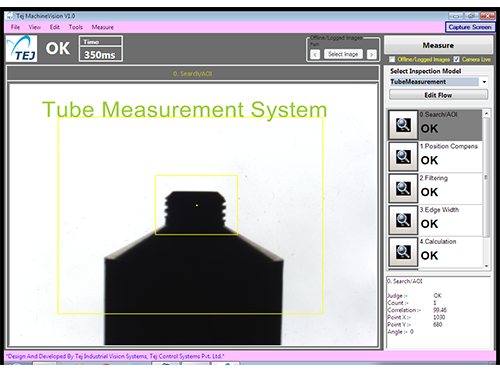

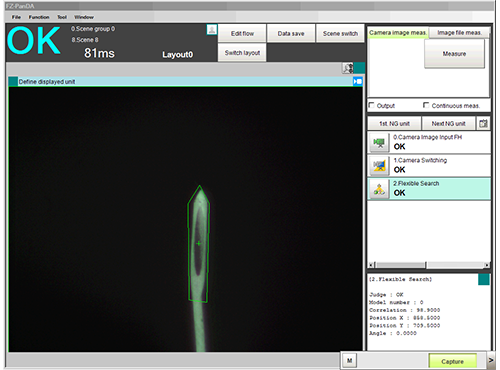

MEDICINAL AND COSMETIC PRINTED TUBES INSPECTION

INSPECTION CAPABILITIES

• Print Defects

• Hole in Tubes