Tyre & Rubber

TEJ control is known throughout the Tyre industry in India. Our experience in the industry has helped us build process wise standardized software blocks to enable easy customization and thereby reduce site commissioning type.

“Coding” software Level I as per IEC1131 Part 3 (functional description, flowchart, function block diagram) and compliance to a number of standards make them leaders in Tyre industry.

The applications commissioned in Tyre and Rubber industry-

- Banbury mixer

- Batchoff

- Stacker

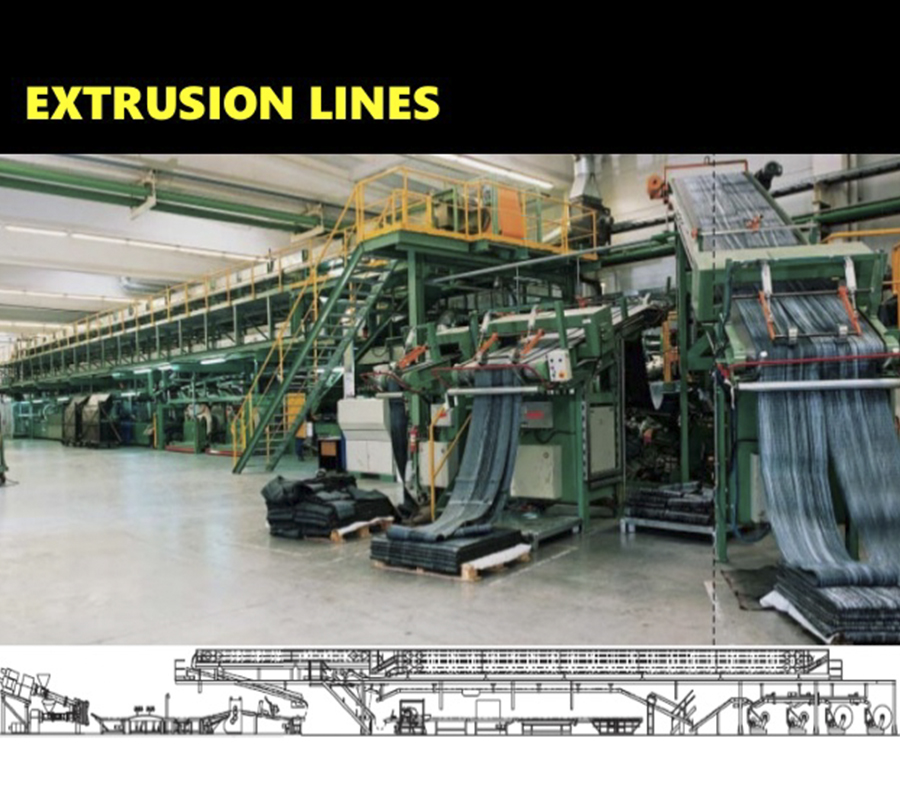

- Extruder + mixing meals + calenders + squeezy lines

- Cooling line + Thread

- Four roll calender

- Squeezy and Bias cutter

- Beed winding

- Tyre building

- Curing press

- Thread and sidewall cooling line

- Windup stations

With Extruder, Tread & Sidewall Cooling Line, Windup Station the salient feature offered by our systems-

- Powerful graphical visual interface and diagnostics features.

- Material tracking and auto threading using Pi based dancer control gives a bounce-less and stable operation at higher speeds.

- Auto weight and width control Customized data logging and reporting. Numerical and graphical representation of Process Capability Cp-Cpk values and SPC on SCADA as per six sigma norms for quality assurance.

- Tread Skiver: Accuracy within 1mm for different cut lengths and a minimum of 21 cuts per minute@1000mm length.

- Windup Stations: Automatic & Smooth Changeover Of Wind-up station

With Bias Cutter/Skiver/Batchoff/Tbm/Curing Press we offer the following salient features:

- Standardized software which can easily be customized on site as per actual requirements. BATCHOFF/TBM/SERVICER/CURING PRESS (with MES optional)

- Accuracy in cut length at higher speeds. BIAS CUTTER (20/21 Pcs/min (1000mm length)

- Future development models with sinamics controls SKIVER will deliver approx. 25/26 cuts very soon.

Over the years we have supplied turn-key Control Systems to several Tyre Industries across the complete spectrum right from Banbury to quality inspection systems

Future developments on our existing equipment’s with latest features of Sinamics/Simotion

- Automatic tread booking.

- Auto Splicing at the bias cutters

- Auto Skiver with more number of cuts (approx. 20%)

- Green Tyre handling systems