Packaging

TEJ Machine vision systems helps in providing quality inspection solutions for packaging of manufacturedproducts. They are a capital investment that pay for themselves while enhancing the quality and brand image at the same time. All companies pay a lot of attention on packaging inspection.

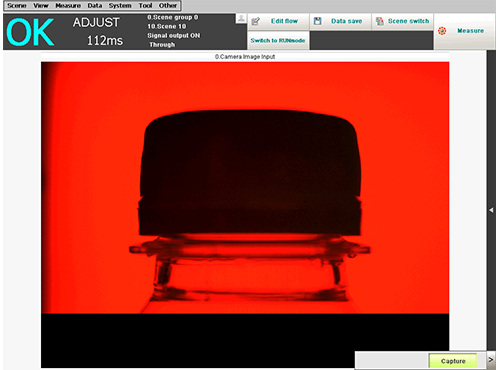

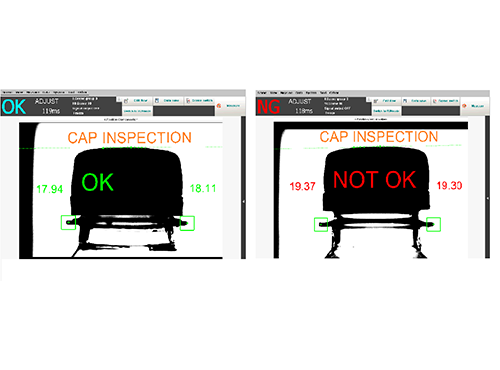

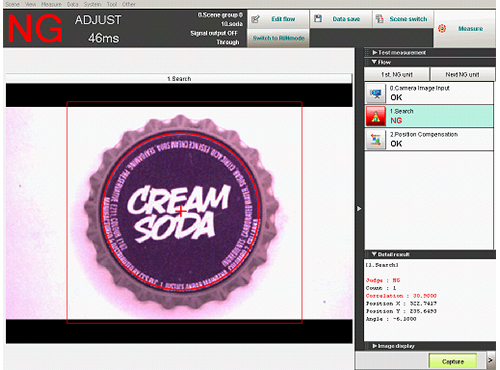

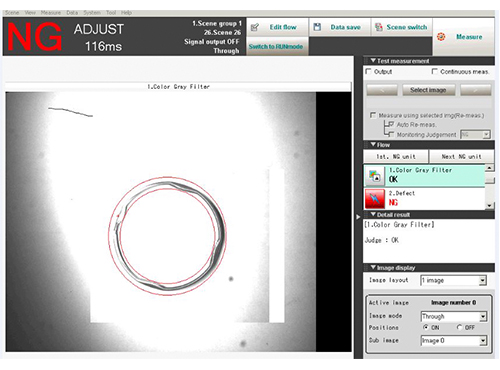

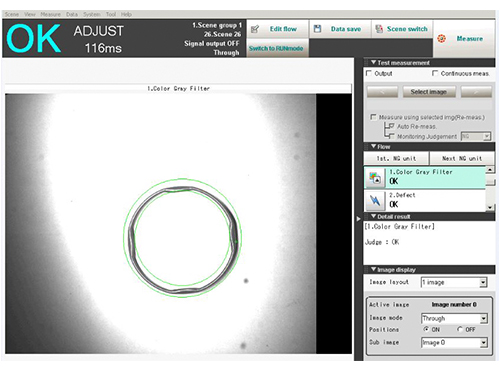

Machine vision systems are designed for inspection of product labels across all market segments and packaging types, with the flexibility to perform level and integrity checks on packaging should manufacturers require them. The machine is designed for its ease of use by operators, its ruggedness and reliability for delivering continuous operation 24 x 7.

The systems perform accurate label and package inspections on plastic containers, glass bottles, jars, screw or snap-on caps, flat packages, cartons and pill packs. The systems are capable of operating at high speeds, without compromising on standards or hindering the flow in manufacturing.

Our Projects

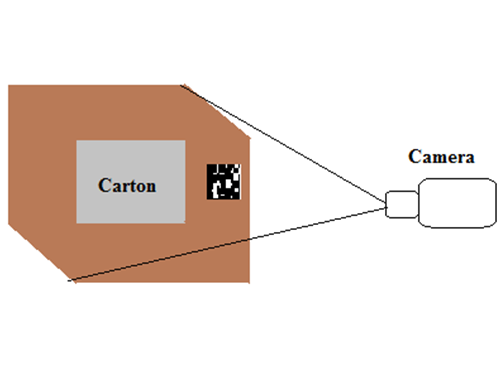

CARTON INSPECTION

INSPECTION CAPABILITIES

• To check Carton packing half Open/Closed