Automotive

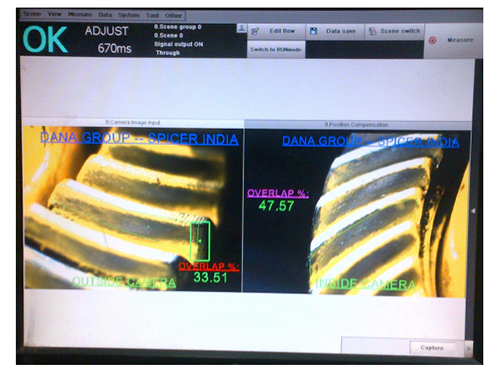

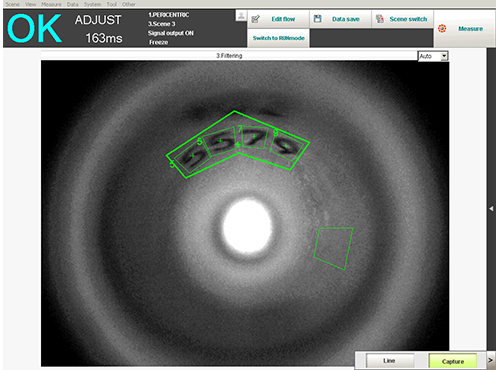

Automated Vision system, quality control and part traceability are common features in the Automotive industry. Robotic Vision inspection is employed extensively to replace numerous cameras mounted at different locations.

From a vision inspection system for checking out of toleranceof components to three decades of being a hard-core automation company, TEJ utilizes this capability to supply a comprehensive solution with the latest pneumatics and field components to detect, measure and control parameters.

Our Projects

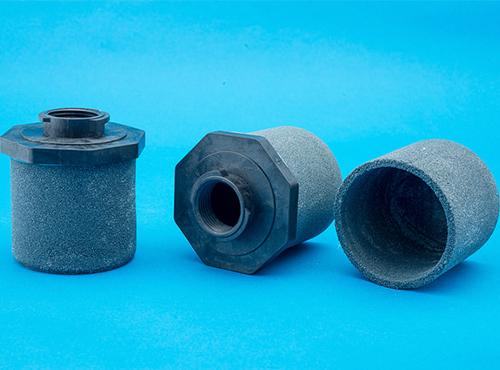

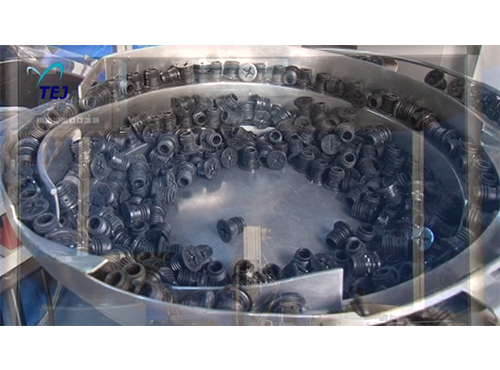

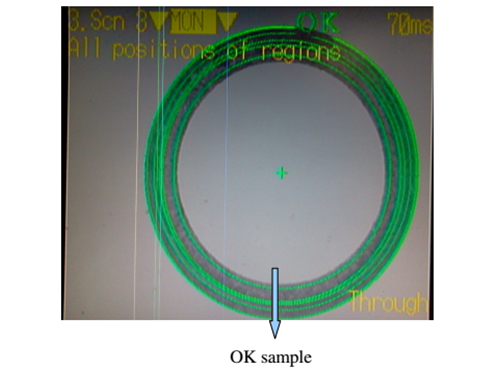

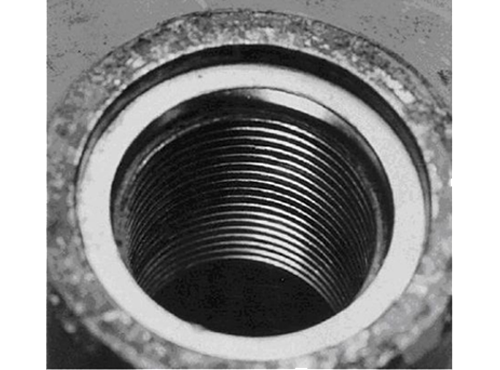

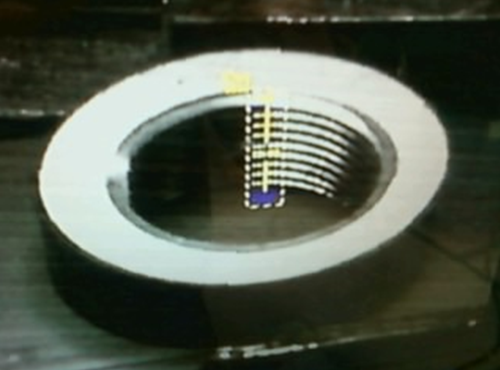

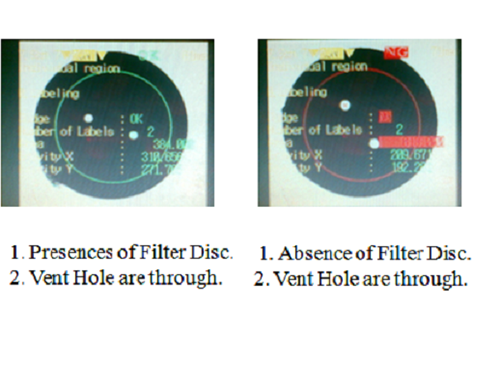

BATTERY VENT PLUG INSPECTION SYSTEM

INSPECTION CAPABILITIES

• Hole detection

• Hole blockage

• Filter disk Presence/Absence

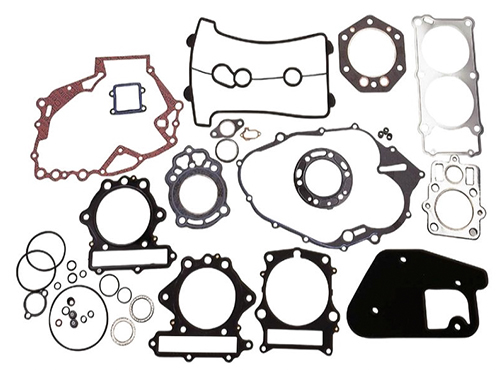

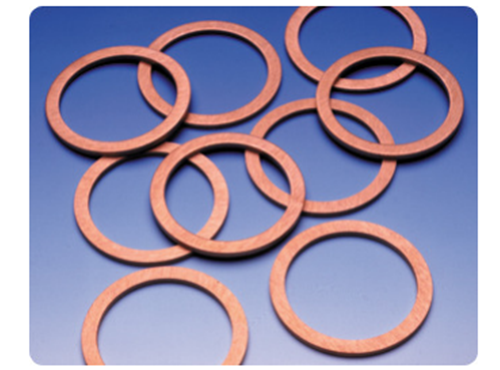

• Gasket placement

HIGH VOLTAGE LEAK TESTING INSPECTION FOR BATTERY CONTAINERS

INSPECTION CAPABILITIES

• Holes