WE ARE GROWING IN BETTER SERVICES AND HOW?

TEJ has realized the importance of Safety and has evolved with SOPs for every process from making cutouts to Wiring, to starting the panel in house and at site. This has ensured a culture of “Safety First” for a “Zero Accident” environment

The adherence to safety norms by all work men is strictly followed andthe responsibility of the Supervisors and Managers to ensure them.

Working with major OEMs and End customers the safety practices have been imbibed over the years and has become part of our Safety checklist.

The culture has made us a preferred automation partner for major customers where statutory compliances and Safety training is a pre requisite before starting any job.

TEJ has been in the business of control panel since 1986 with a turnover of Rupees 740 million in 2018-19 with an Onicracredit rating of SE-1B. TEJ has grown to a company with a working area of 2300 square metersand serving a total of more than 4000 customers per year.

With a track record of executing projects in nearly all industries and distinction of standing 2nd among Thane small scale industries for Outstanding performance in Thane district.Financially backed up by strong Bankers& confirmed by ONICRA, we can execute a single project of over 200 million value.

With expertise of the past three decades and R&D department to supplement our endeavor for taking up new challenges, TEJ has become a dependable name for complex projects.

The company has evolved to supply world class products at economical cost. Our association with world leaders and major customers has made us realize the importance of project management. TEJ has introduced 5S and LEAN manufacturing in its working area and with an ERP implemented, the company has been able to deliver projects in time.

With products from Siemens, Omron, Phoenix and Rittal, inhouse panel building capacity and Machine building division, TEJ has become a favored destination for Automation needs and electrical products. The expertise in selection, design, installation and commissioning and with design software from E- plan and Solid Edge makes TEJ a one stop solution forour customers.

With electrical and mechanical manufacturing under one roof TEJ has control over quality in all aspects of the product. The customer can directly interface with our Engineers for design suggestion and view the simulation of machine before manufacturing.

Being in the business for a long time we have gone through the phase of missing deadlines, price escalation and open-ended Terms and Condition and mismatch in description and part numbers, BOM and drawing. It was difficult to reply all queries on the status of panel ordered on us which the customer rightfully deserves to know. Experience, adaption of cloud-based ERP and our desire to keep the customer apprised has ironed out these issues. The present system has eliminated manual dependency and given the customer the access to monitor the progress. Drawing & BOM can be approved online, adherence to BOM and time line can be checked and suggestion during design and also manufacturing provided.

Compare it with old system where views once made were free zed for production and customer had no option but to trust his Electrical partner. Of late, TEJ’s policy is to introduce transparency to maximum possible level.

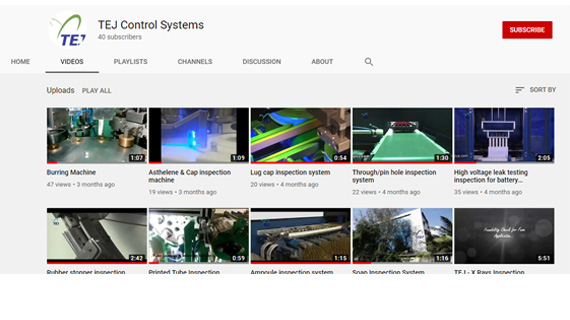

The components of the panels are selected with care to comply with the standards of the destination country. The enclosure by default has UL,CSA,TUV ratings, the automation components, switchgears, SMPS, terminals, meters, controllers are selected from brands which have world acceptance/warranty or as per the approved make of customer. TEJ have offices in North & West India and representatives in Canada, Australia and UAE.Documentation is in line with accepted norms of Siemens. With time tested methods of providing on line support by Team Viewer, through Internet via module &IIOT, TEJ has been able to support customers worldwide to keep their systems running. Of late we envisage the concept of providing Robots and Vision Inspection system on “Pay as peruse “with IIOT incorporated in the control of machine.

With ERP designed in line with the inputs of our experience, the execution of project takes place in a methodical manner. The following process are followed.

- Deal is created when inquiry is received

- A Kick off meeting on receipt of PO

- The responsibilities for every stage is mentioned in ERP and transparent to the customers as they have access.

- The status of project and expected delivery period accessible to all concerned parties including customers.

- Factory acceptance test can be done on line without the customer’s presence in our works and interaction done as if they are present.

- Post commissioning the option of monitoring, data analytics to help in preventive maintenance and enhancement of efficiency is offered to customers.

The business of system integration is changing fast with price going downwards and “delivery required yesterday”. It starts with the process of submitting a quote, interaction with the customer, finalization and execution, all done in a challenging period. TEJ has created blocks which are compiled to arrive at the right quoting figure, designed templates for submission of drawing and moving towards automized purchase. The aim is to deliver in minimum time, at every stage and synchronize the different stages for completion of the project in minimum time. This service has started to bind our relationship, and has further strengthened it when we are there for customers in their hour of need or a machine breakdown.

Being in the business for more than three decades, we have listed down a few milestones, TEJ has jointly achieved with our customers:

- Siemens System house with largest Sales Volumes in year 2017-18 in Western India

- Awarded as TISSA Outstanding Achievement Entrepreneur Award – 2018

- Awarded the 2nd prize in Small Industry sector of Thane by Government of Maharashtra in year 2017-18

- Awarded as RITTAL- Best Channel Partner 2017 all over India. More

- Credible ONICRA rating and solvent to take large projects

- A plot area of 3402 sq mts, Production area of 2300 sq mts and 6500 sq mts of carpet area

- With largest number of Vision Inspection system installation Pan India

- Commissioned the largest number of automation systems in Tyre Industry Pan India

- Manufacturing panels for Siemens in line with exacting standards of Siemens since 2017.

Yet we say we are beginning our journey, and have miles to go.