FMCG

The large numbers of products produced by FMCG cannot be inspected manually without causing a bottle neck in production or loss of brand value. Vision inspection plays a huge role in the different stages of production.TEJ systems are designed for its ruggedness, longevity, reliability and ease of operation in inspecting single or multiple defects in one machine.

The flaws in dimensions, packaging and printing on labels of the product is inspected without hindering the flow, speed and accuracy.

Containers, bottles, packet, sachet are inspected to avoid leaks, spillage before reaching the market place. Brand value is quintessential in the marketing of FMCG products and unintentional errors causes huge damages to the brand image. The print inspection and OCR safeguards misinformation by verification of labels for bar codes, batch coding, expiry date to avoid any legal action.

TEJ has qualified in meeting the challenge of FMCG customers brand name. The experience of FMCG with TEJ for providing a reliable, rugged and economical solution has led to a long, continuous association with major FMCGs.

Our Projects

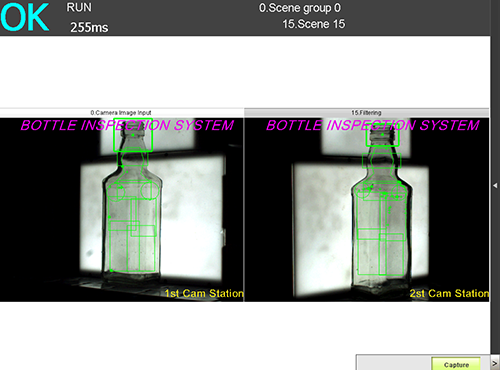

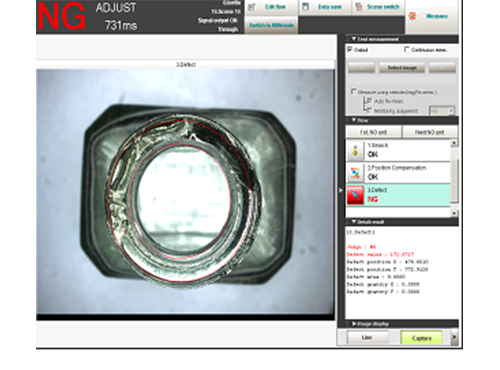

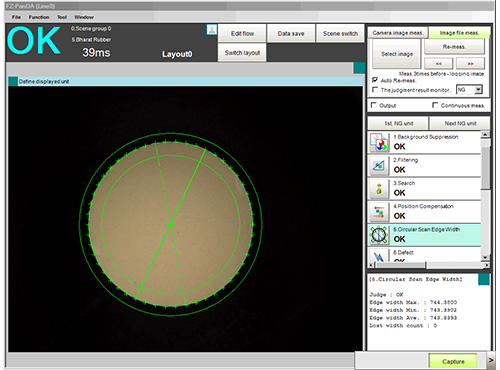

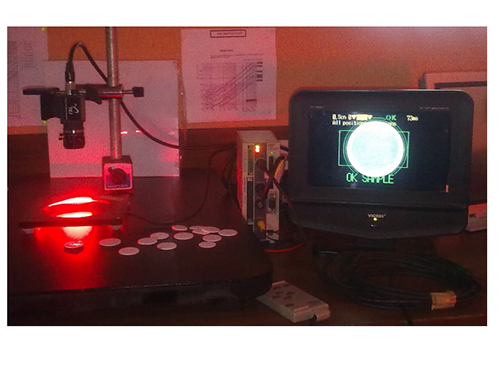

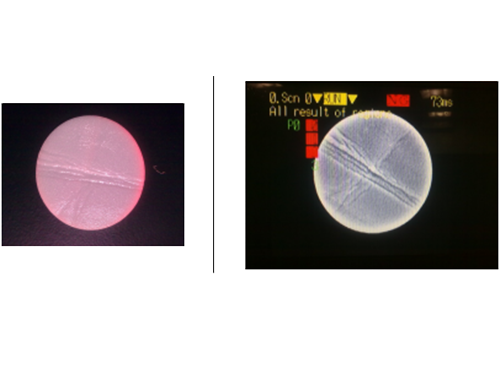

BOTTLE INSPECTION SYSTEM

INSPECTION CAPABILITIES

• Neck Inspection

• Sunken neck, broken seams, ring seam cracks, neck tear

• Surface inspection

• Body dimensions, stones, seed, body cracks, blisters, molds, bulges, wrinkles, dirty bottle, oil marks, glass string, brush mark, pressure cracks, wash marks, sunken sides, thickness

• Base inspection

• Uneven base, foreign object

• Other inspection

• Label presence, alignments, label wrinkles, print presence & absence, fill level