Agriculture

With prices of agricultural products not matching the rise in labour component, further complicated by imports, the industry has realized the importance of automation and is making a paradigm shift. The “Sorting and Grading” of nuts including Cashew nuts, fruits and Vegetables, analysis of grains before planting, food such as meat& diary needs an efficient Non-Destructivevision inspection system which is simple, low cost, with high speed andprecision.

Machine Vision provides information of the object in the invisible area and can be useful to determineheat given to mature plant, diagnosis plant diseases and in determining the variety, puberty, maturity and quality of plants and vegetables. The use of X-ray for detecting diseases or other defects can also be added to the challenges TEJ conquer.

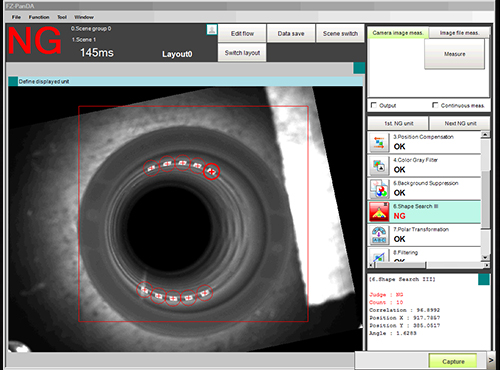

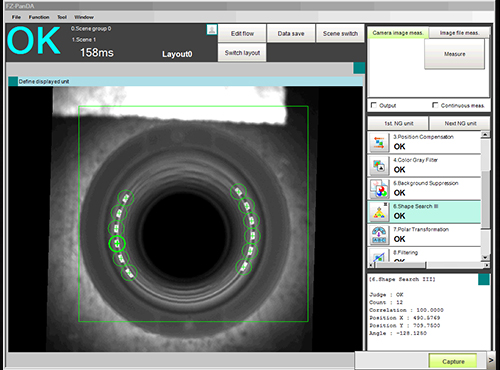

The growing automation calls for accessories like drip irrigation systems and dripper being produced in large scale. Vision system is used extensively to inspect the quality of these components before it is dispatched to the market.

With speed and high precision of vision systems, agricultural and the food industries globally have found a voracious appetite to replace manual systems by this advanced and non-destructive monitoring system.