Tyre & Rubber

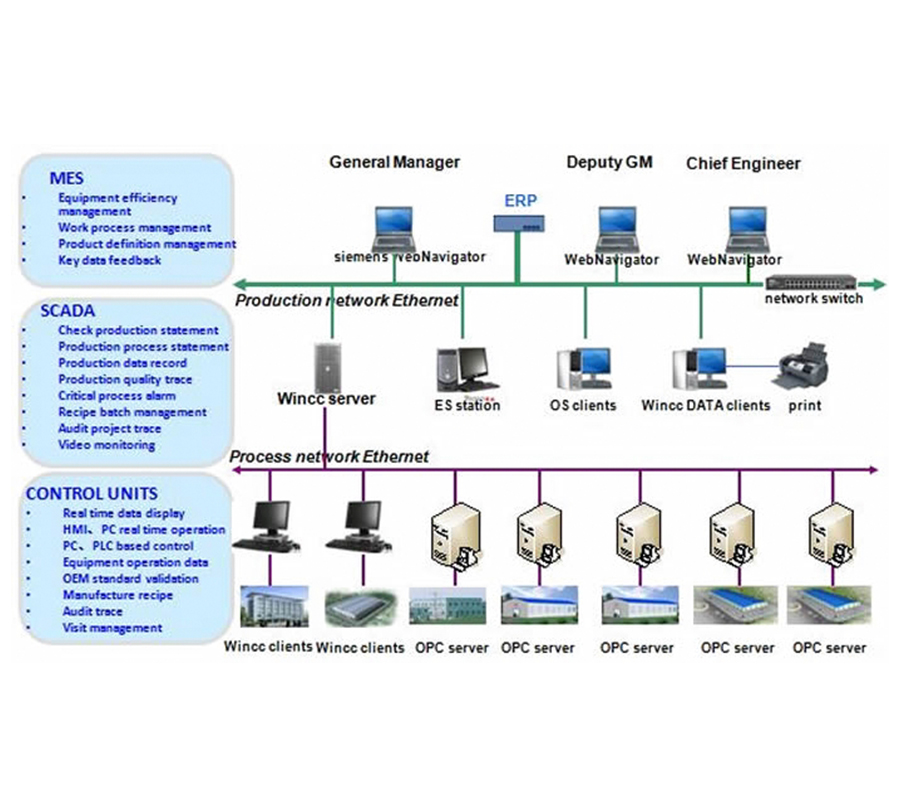

TEJ control is known throughout the Tyre industry in India. Our experience in the industry has helped us build process wise standardized software blocks to enable easy customization and thereby reduce site commissioning type.

“Coding” software Level I as per IEC1131 Part 3 (functional description, flowchart, function block diagram) and compliance to a number of standards make them leaders in Tyre industry.

The applications commissioned in Tyre and Rubber industry-

- Banbury mixer

- Batchoff

- Stacker

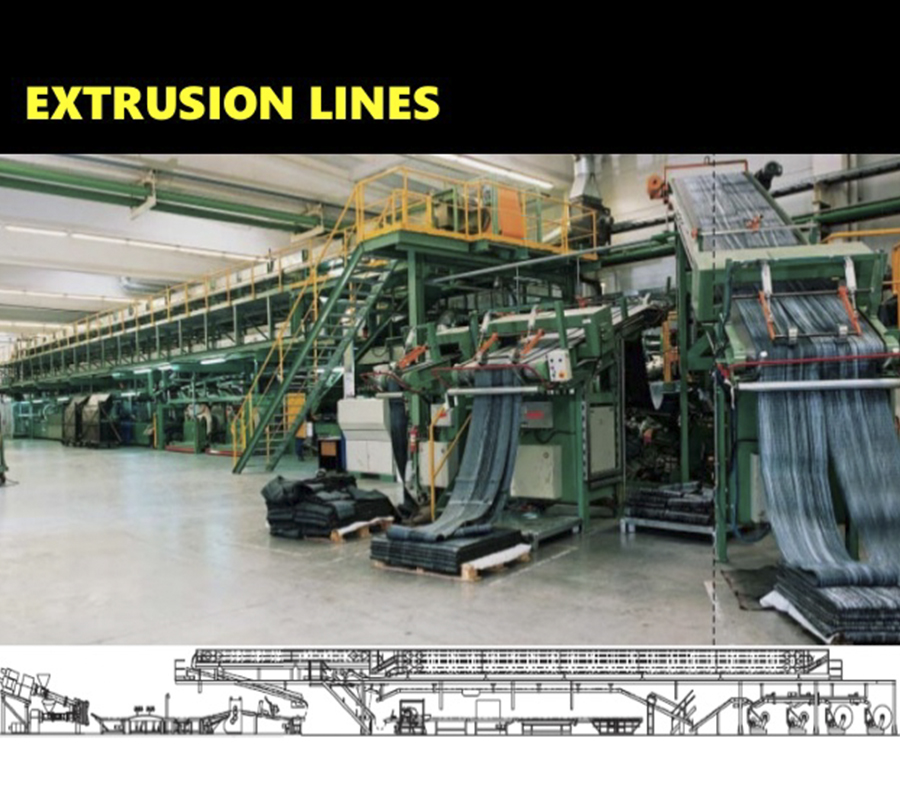

- Extruder + mixing meals + calenders + squeezy lines

- Cooling line + Thread

- Four roll calender

- Squeezy and Bias cutter

- Beed winding

- Tyre building

- Curing press

- Thread and sidewall cooling line

- Windup stations

With Extruder, Tread & Sidewall Cooling Line, Windup Station the salient feature offered by our systems-

- Powerful graphical visual interface and diagnostics features.

- Material tracking and auto threading using Pi based dancer control gives a bounce-less and stable operation at higher speeds.

- Auto weight and width control Customized data logging and reporting. Numerical and graphical representation of Process Capability Cp-Cpk values and SPC on SCADA as per six sigma norms for quality assurance.

- Tread Skiver: Accuracy within 1mm for different cut lengths and a minimum of 21 cuts per minute@1000mm length.

- Windup Stations: Automatic & Smooth Changeover Of Wind-up station

With Bias Cutter/Skiver/Batchoff/Tbm/Curing Press we offer the following salient features:

- Standardized software which can easily be customized on site as per actual requirements. BATCHOFF/TBM/SERVICER/CURING PRESS (with MES optional)

- Accuracy in cut length at higher speeds. BIAS CUTTER (20/21 Pcs/min (1000mm length)

- Future development models with sinamics controls SKIVER will deliver approx. 25/26 cuts very soon.

Over the years we have supplied turn-key Control Systems to several Tyre Industries across the complete spectrum right from Banbury to quality inspection systems

Future developments on our existing equipment’s with latest features of Sinamics/Simotion

- Automatic tread booking.

- Auto Splicing at the bias cutters

- Auto Skiver with more number of cuts (approx. 20%)

- Green Tyre handling systems

Pretreatment and Painting of Metal

Control panels for automation of wagons in degreasing, pickling, drying and phosphating was supplied to major metal finishing OEMs. Panels for anodizing, zing, nickel chrome and copper tin plating were also supplied.

Painting is very delicate process that provides finishing to the substrate. Color mixing, viscosity and temperature control.Regulation of paint flow and pressure to ensure a uniform deposition of paint and powder coating, required interface with robots. The highest quality of consistent finish with decided thickness was possible with automation. Booth control and washing machine automation was also commissioned by our Engineers.

Oil & Gas

TEJ has experience in oil & Gas extraction processing, transportation and dispensing. The application demands efficiency and safety.

Oil and gas applications includes

- Sulphur and Argon recovery

- Mud & cement pumping

- BOP (Blowout protection unit) & Top drive control

- Storage of natural gas and dispensing stations

- Compression at pump station

- Monitoring flow and distribution at dispensing stations of natural gas, petrol & diesel.

Some of the applications were executed in extreme conditions of oil rigs at off-shores. We are also available to provide our services for maintenance, program development, modification & commissioning of control systems at off-shore and on-shore rigs..

Newspaper & Printing

Newspaper industry is unforgiving in terms of reliability as news cannot be printed the next day. The upgradation and retrofitting of the machine should failure proof and only trustworthy automation houses are assigned the job. Similarly, for printing precise images on packaging wrappers and synchronization of different color printing stations is major challenge. With our expertise and specialized function blocks we have achieved desired accuracies at various printing & packaging manufacturers.

The project includes

- Plate processing

- Machine pgradation

- Stacking of newspapers in bundles

- Offset Printing line

- Lamination line

- Slitter

- Metalizing

- Label cutting

The above application includes upgradation of microcontroller to regular PLC and retrofitting of obsolete systems with the current controls. This has saved the lot of downtime, uncertainty and spare replacement cost which was astronomical.

Printing requires lot of precision and high skill in motion control.

Textile

Textile has been backbone of our Indian fashion and clothing culture. It has been one of the oldest and ever-growing industry of India. In the era of evolving clothing needs of India, there is a constant desire to deliver quality product in a dynamic market of textile. To fulfill the demand and quality needs of industry, automation has been playing pivotal role. We at TEJ control has been partner in developing automation needs for various textile application. Some of our work are as follows.

- Bleaching Machine.

- High Temperature, High Pressure dyeing machine

- Power-Frame Stenter

- Coating line.

Waste & Wastewater Management

Waste water management system have come a long way and has become mandatory for industries producing effluents. Safety, efficiency and reliability are the basic requirements for building the system. Today they are controlled and supervised by PLC, HMI & SCADA.

With new technologies available we have commissioned systems for Remote controls of pumps, Blowers and Diagnosed & rectified PLC program and breakdowns from remote locations.

Frequent water treatment projects:

- Well and surface source pumps

- Filter consoles

- Purification systems – RO, UV-HSRO-EDI, MGF &Softners

- De-gasifiers

- Reverse osmosis

- In-plant and remote pump controls

- Tank level monitoring

- Raw sewage lift stations

- Aeration basins

- Dissolved oxygen controls

- Clarifiers

- Dewatering & effluent systems

Projects–

- PrajHipurity – Water treatment plant.

- Elex India Pvt. Ltd.

Amusement Park

We have worked with one of the biggest Amusement and theme park of India. Our technical expertise in automation has added more fun element in simulated flying experience of “I for India” ride – Witness the magnificence of India in a unique flying experience.

The safety element plays a crucial role to have accident free rides.

Automobile

TEJ has supplied systems for automobile industry in transmission, engine, body, Axel and vehicle product units. Furnace for hardening the components of transmission P.U. and monitoring the furnace has been successfully commissioned by M/s TEJ. Monitoring and data logging for posterity and provision of alarms to designated personnel was an added feature.

-

- A complex poke-yoke was supplied to the Engine and Transmission product unit to ensure SOP in assembly of nuts & bolts at each workstation.

- A pick & place system for welding of body components and upgradation of 300TON press was supplied to body product unit.

- Upgradation of multi-head drilling system from a relay logic to PLC was also supplied. The final assembly of the vehicle on slat conveyor was automated with provision of redundancy in drive and plc using contactor logic. The innovative cost reduction method using lower series PLC for redundancy was appreciated.

- The automotive plant is large in size with number of panels and tripping of any panel will result to breakdown down the line. Our cooling solutions has ensured more than 50% energy saving and reduction of downtime.

Food & Beverages

The volume of food and beverages production has multiplied many folds and this could not have happened without automation. From processing raw ingredients to packaging and transportation of end products, optimized efficiency and cost plays major factor to be competitive. At TEJ, experience over the years has given us understanding of the specific requirements of this industry.

Incidentally TEJ control started the business by manufacturing bottle washing systems, crater and de-crater, filler and palletizer in beverage industry.

Our system includes

- Conveying and processing

- Batch production

- Automated packaging

- Power & Utilities management

Projects

- United beverages.

- Hindustan coca cola.

- Dynatron

Metal & Steel Industry

The steel industry is a barometer for the state of economy. The urgency of upgradation of this industry fluctuates on big way. TEJ has been involved in number of applications for upgradation of Electrical, Automation and SCADA, as given below

Rolling Mills

- TMT Bar & wire rod mill

- Cold rolling mill (2Hi, 4Hi, 20Hi)

Process lines

- slitting,

- Cut to length,

- Tension leveling line,

- Blanking line,

- Galvanizing line,

- Annealing & pickling line,

- Degreasing line,

- Color coating line.